Milling

We can't expect things to change if we keep doing the same thing– Albert Einstein

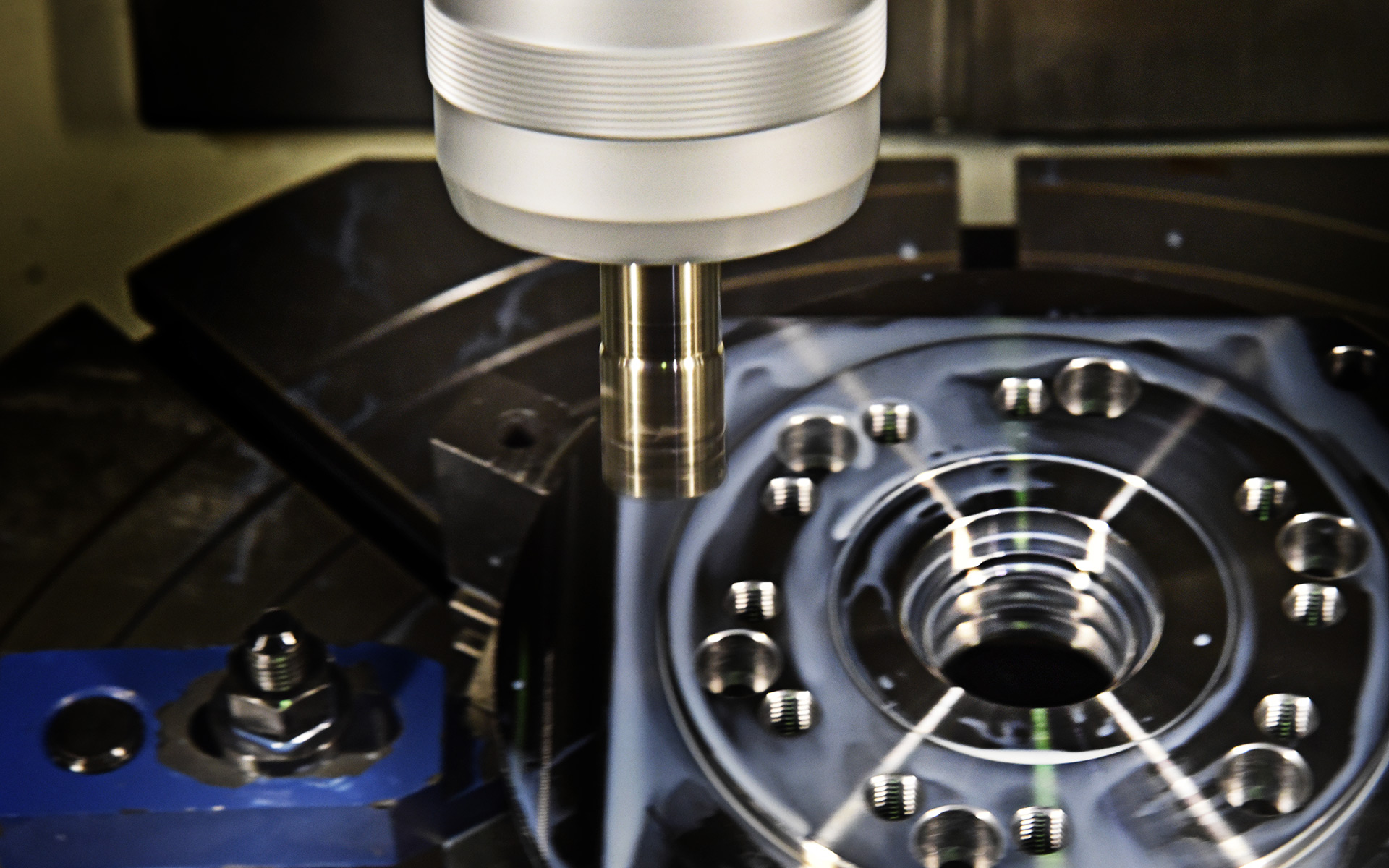

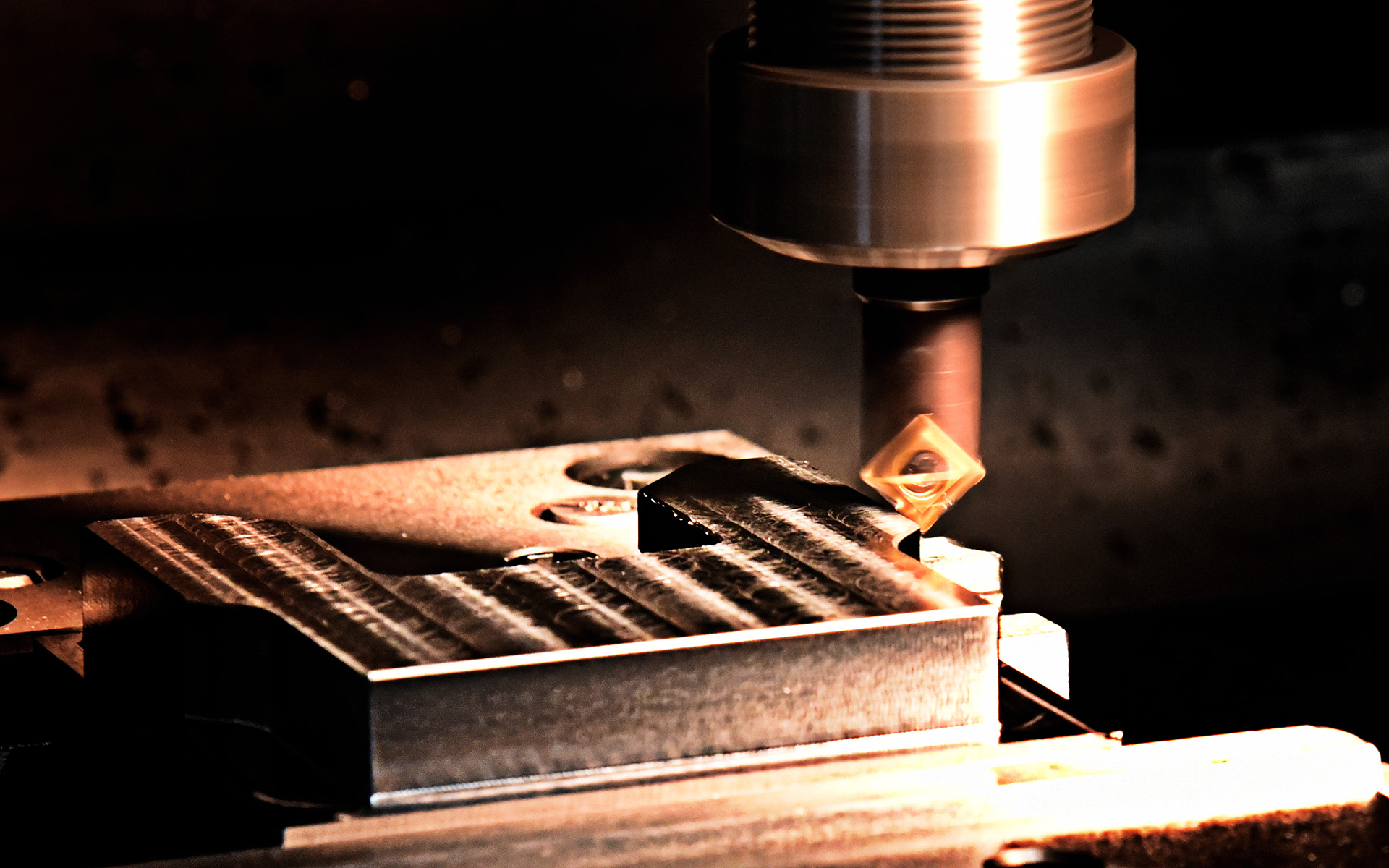

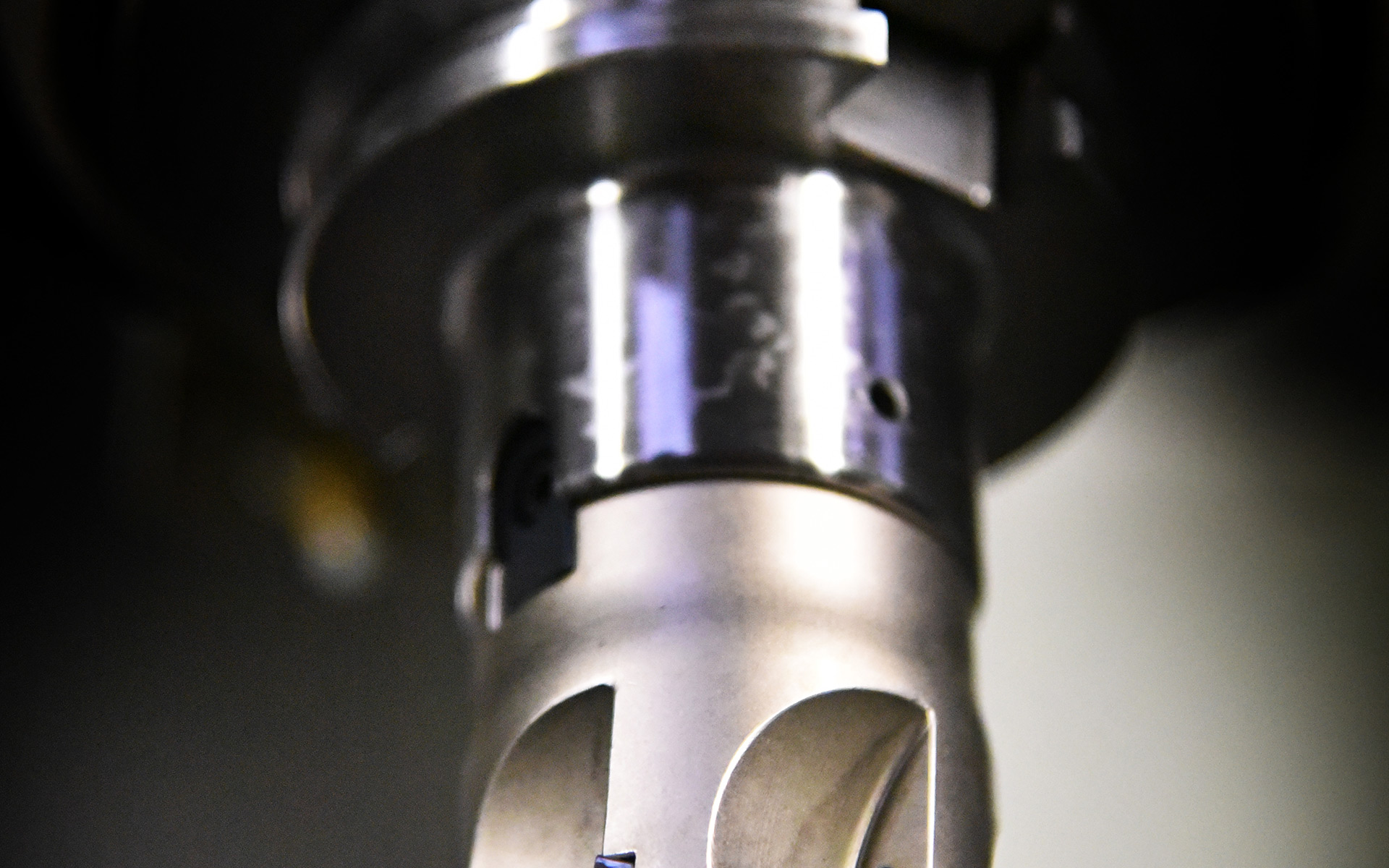

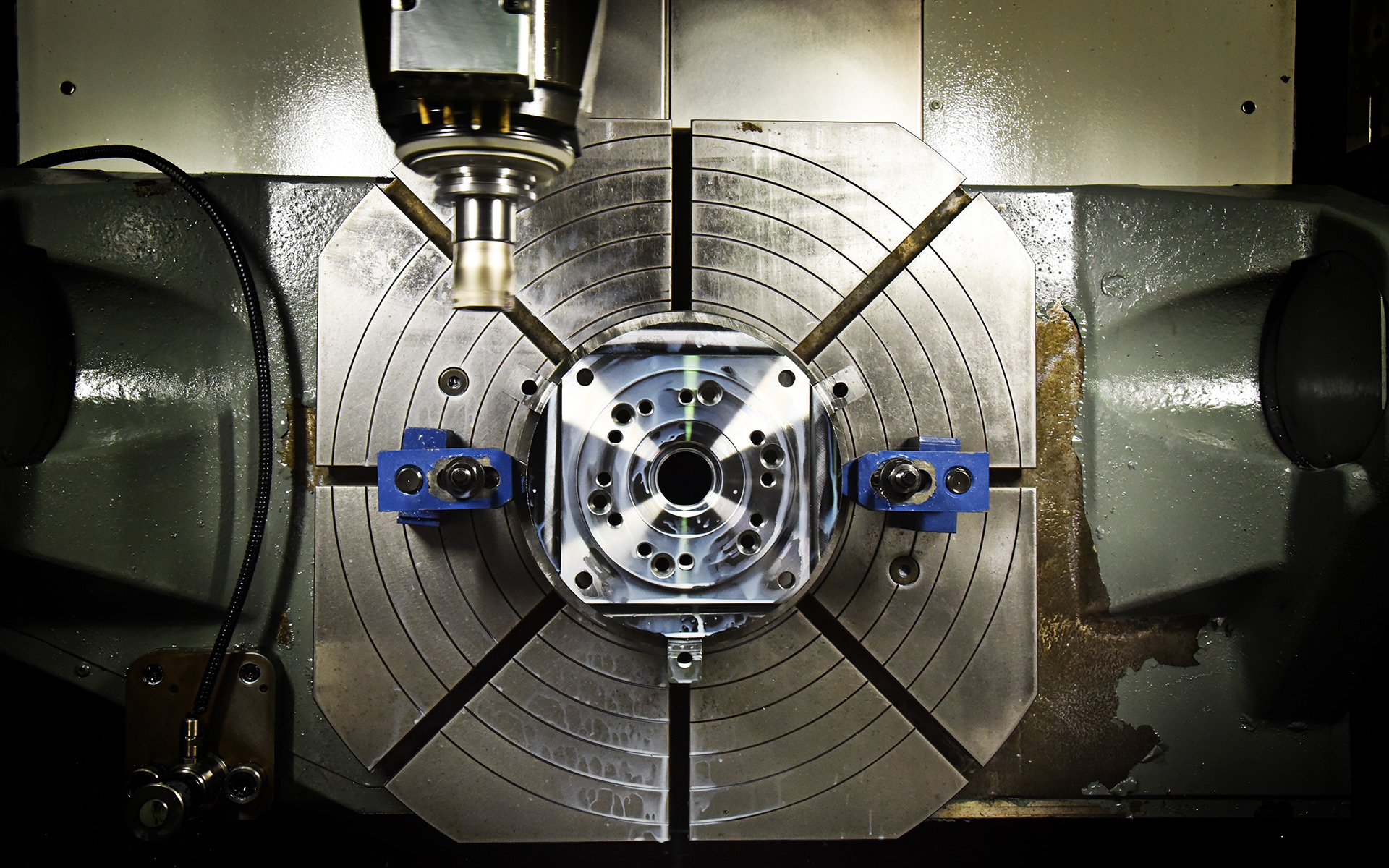

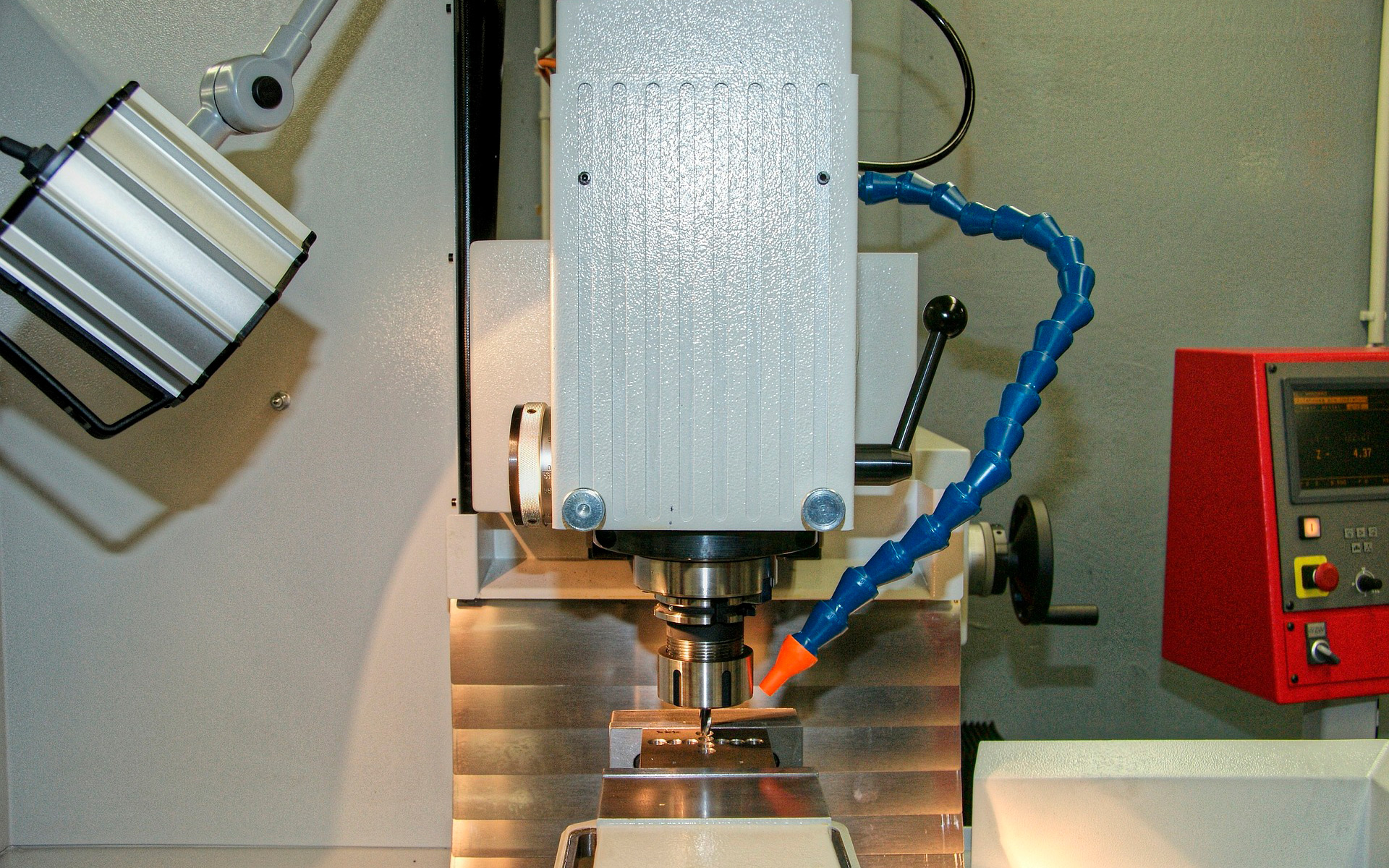

Milling consists mainly of removing material from a part machined with a multi-edged rotating tool, called an insert, which performs movements in all directions of the three possible axes on which the table can be moved.

With the increasing use of CNC milling machines and lathes, the milling operations that can be performed with this type of machine are increasing, while milling has become a multi-purpose machining method.

The development of tools and technologies in the 4.0 industry has also contributed to the creation of new milling possibilities and has significantly increased the productivity, quality and precision of the operations performed.

Our technical department is at your disposal to study your project without any commitment and to advise you on the opportunities and possibilities that we can offer to reduce costs and industrial productivity.

Our highly qualified professionals, together with the latest technology in the sector and constant quality control, make our milling services a guarantee in industrial subcontracting.

Here we identify some of our most common services:

Milling planing

Milling profiles

Milling of slots

Milling holes and cavities

Milling and cutting of gears

Milled lathe

Milling of slots

Logically our services do not end here, based on our experience in high-precision machining, our technical department assesses your needs to give you the best advice and the best comprehensive service.

Our MILLING services can be applied in all areas of machining and milling, these are some of them.

Milling for the automotive industry

Milling for the aerospace industry

Milling for the railway industry

Milling for the metal industry

Milling for the nuclear industry

Milling for the aviation industry

Milling CNC

The CNC machine is an electronic technology that allows the machine to work in almost total autonomy with very high standards of repeatability and process precision.

In CNC milling, the operator inserts instructions into the computer that controls the machine; these instructions, called G codes or NC codes, define the part geometry and tool path as a grid of points that can be easily handled by a computer

Our company works with 51 MACHINES CNC and thanks to our experience we guarantee the highest precision and quality.

Depending on the configuration of their moving parts we can differentiate them

At this point, the machine operates autonomously and the operator only controls the processing, intervening in the event of a fault.

Through CNC milling it is possible to obtain machining with an accuracy of one micron (one ten thousandth of a millimetre).

When a CNC milling machine has an automatic tool change, it is called a machining centre.

Milling planning

Mobile column milling machine

Mobile tabletop milling machine

Bridge milling machine

Milling and cutting of gears

85% of our offers become orders

We will give you a free quote without obligation