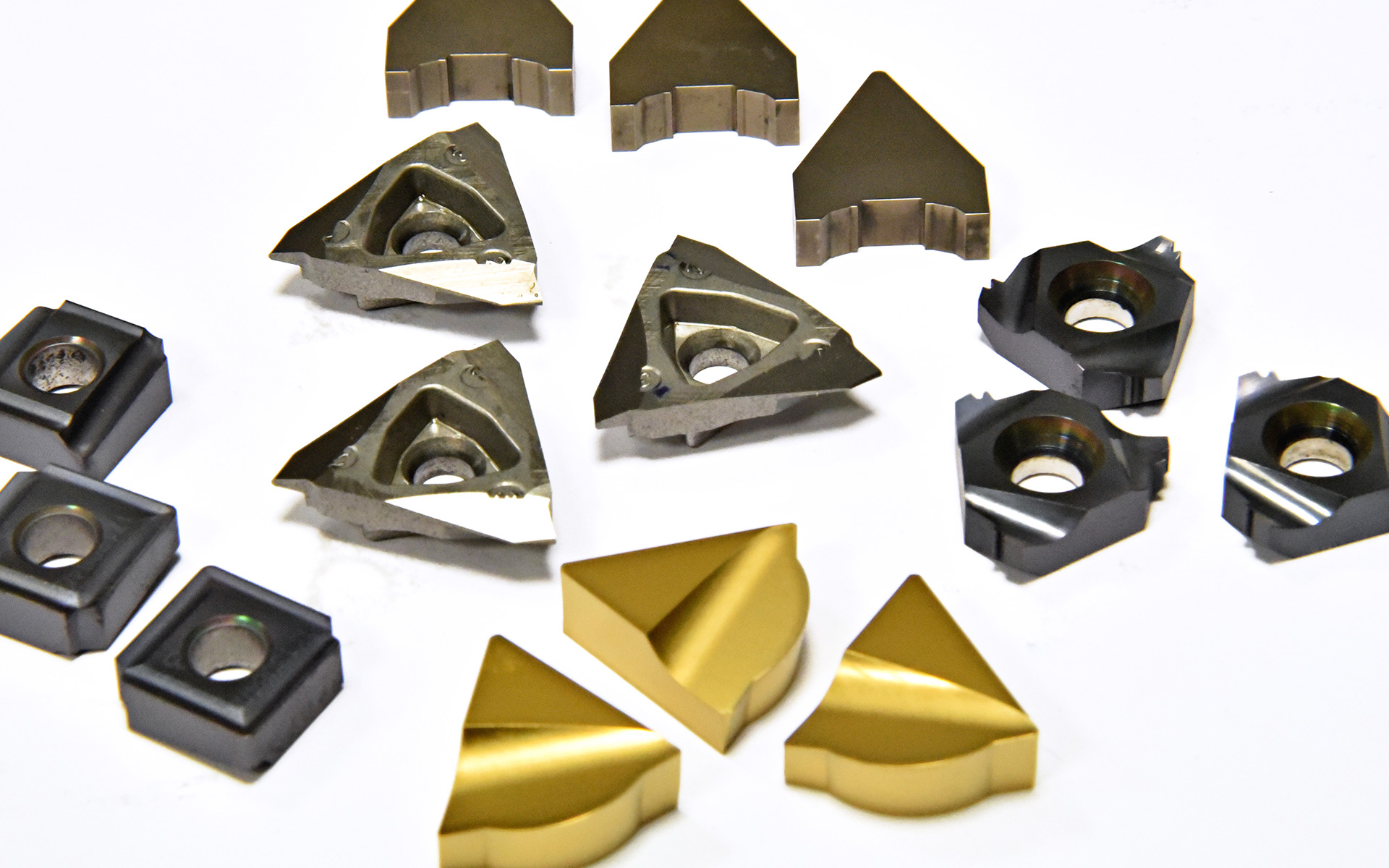

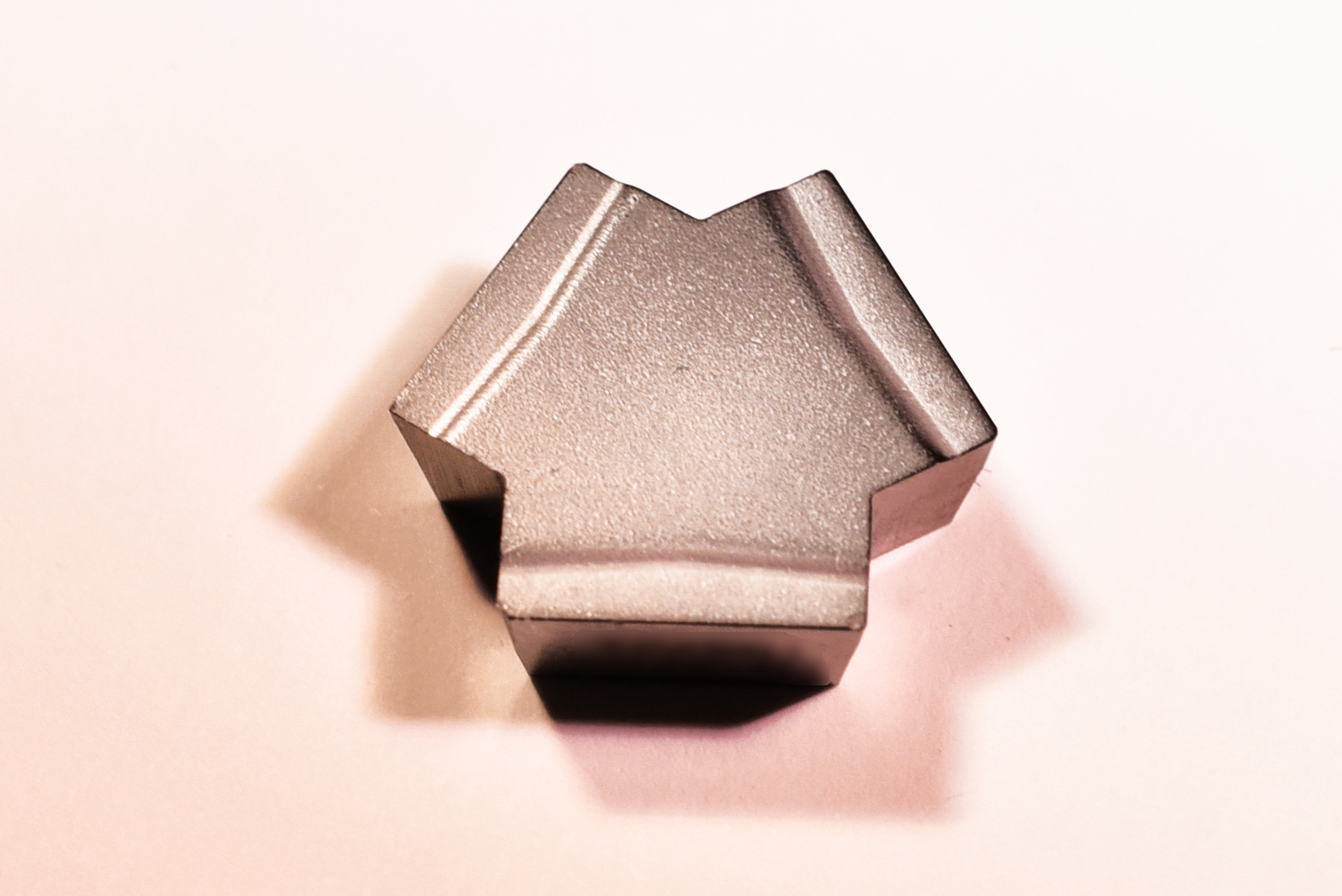

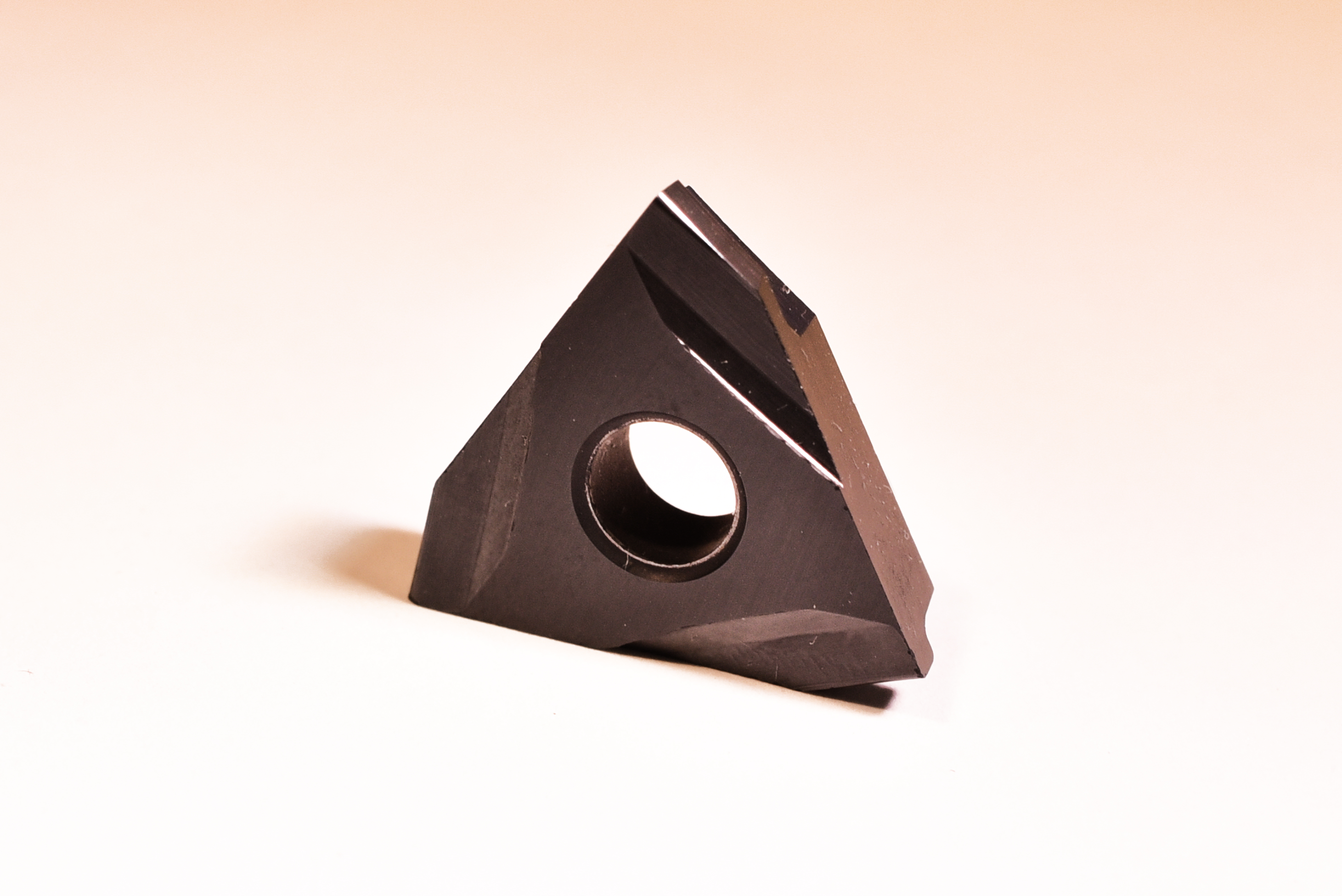

Cutting tools - Inserts

A person who has never made a mistake, has never tried anything new.There are many types of inserts that can be used with different cutting modes and speeds depending on the type of material or machining.

Single point tools are used for turning, forming, planning and cutting material. Milling, grinding and drilling tools are often multi-edged tools.

The materials of the teeth or cutting inserts must be harder than the material to be cut and the tool must be able to withstand the heat generated during the metal cutting process.

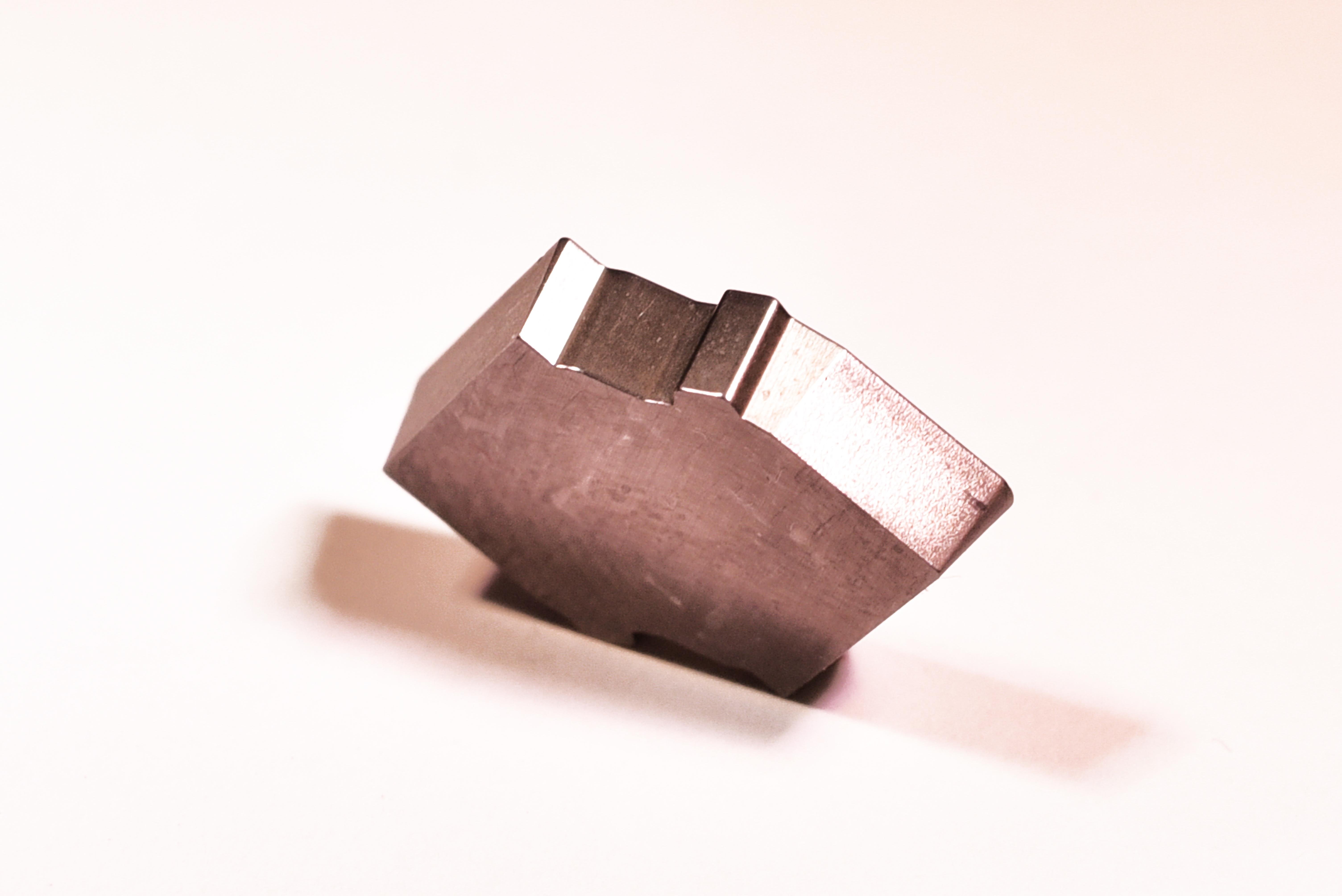

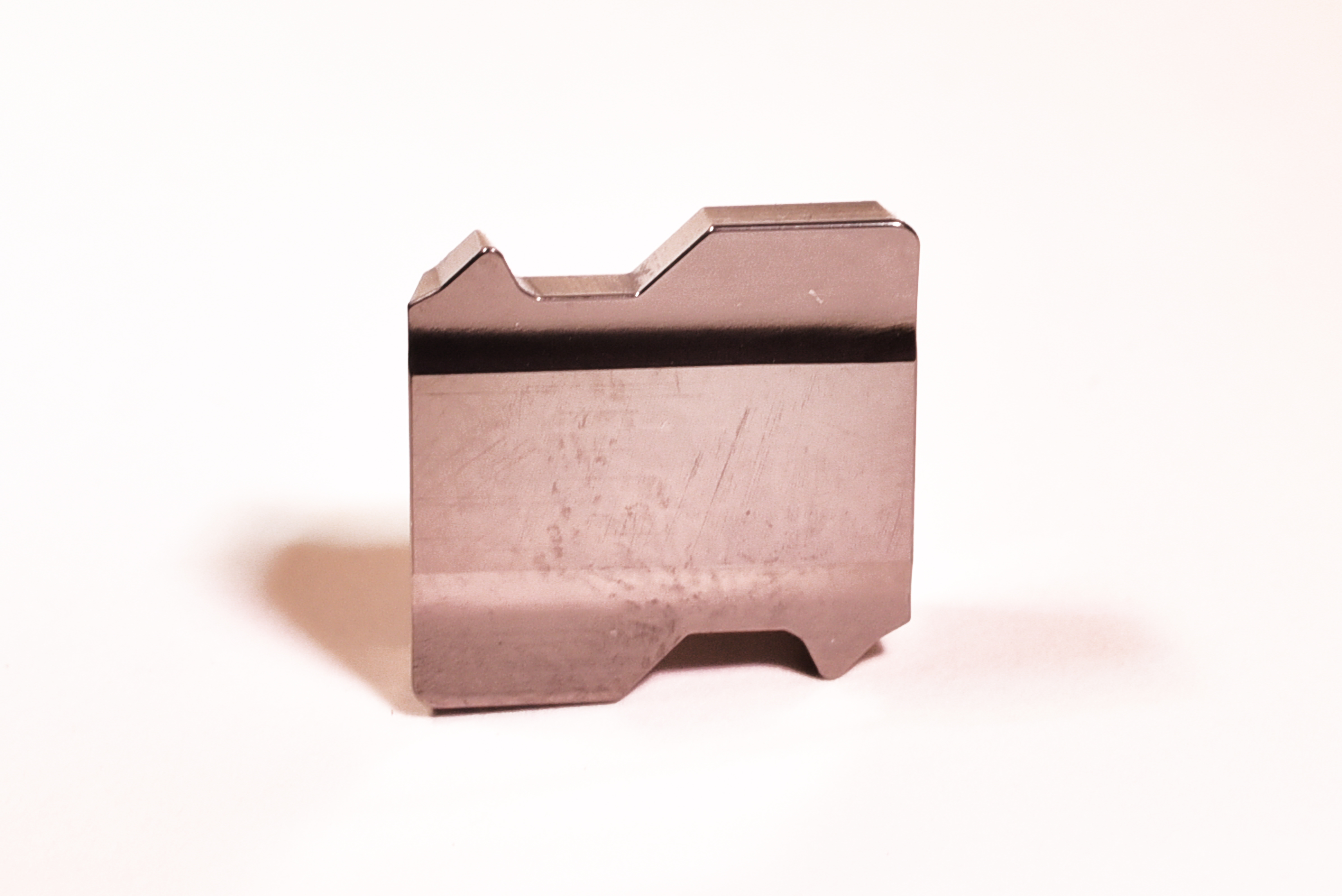

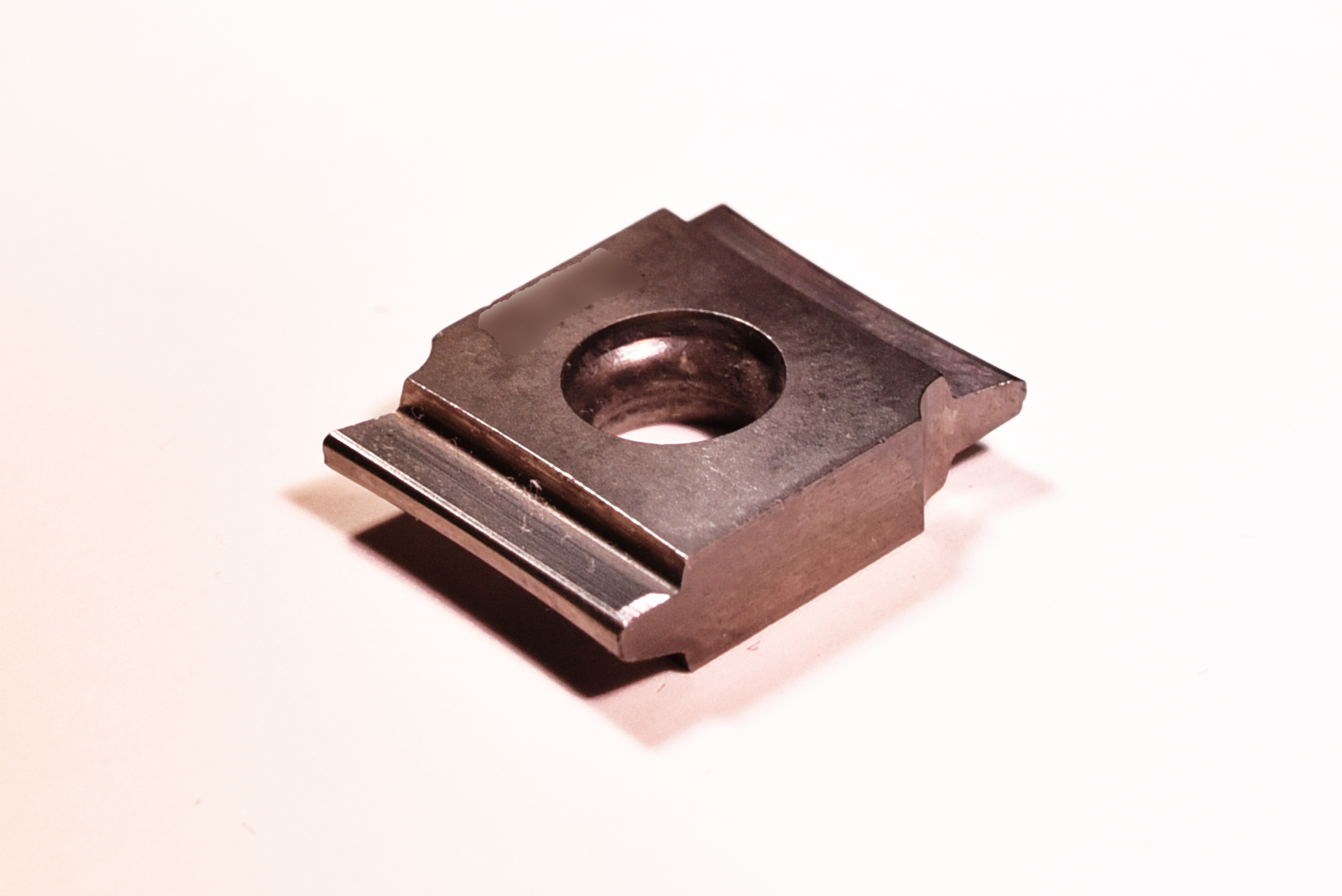

In addition, the tool must have a specific geometry, with separation angles designed so that the cutting edge can come into contact with the workpiece without the rest of the tool being dragged out of the workpiece surface.

The angle of the cutting surface is important, as is the width of the groove, the number of grooves or teeth and the size of the margin.

Our technical department is at your disposal to develop your project without any commitment and to advise you on the opportunities and possibilities that we can offer to reduce costs and increase industrial productivity.

Our manufacturing process for inserts is based on the use of wire EDM machines, which allow us to produce the element itself quickly and correctly. We are equipped with special platforms for the mass production of inserts. The cutting procedure is applied by CAD programming and numerical control program preparation.

Our services also include the supply of titanium or zirconium inserts, which ensures greater wear resistance (demonstrated by specific tests).

In addition, we manufacture special inserts according to special requirements, and we offer inserts made of hard material that meet industry standards and are guaranteed to meet ISO 9001-2015 quality standards.

85% of our offers become orders

We will give you a free quote without obligation