Heat treatment

Failure is a great opportunity to start over with more intelligence.– Henry Ford

Heat treatment is the set of all heating and cooling operations, under controlled conditions of temperature, dwell time, speed, pressure, of metals or alloys in solid form, to improve mechanical properties, in particular hardness, strength and elasticity.

The materials to which the heat treatment is applied are essentially steel and cast iron, composed of iron and carbon. Ceramics can also be subjected to various heat treatments.

The coating, as a surface treatment, has undergone a constant growth in recent decades, this is because the industrial evolution in the field of optimization of production and competitiveness has aimed to increase the life of the tools while maintaining the final cost.

Titanium and aluminium nitride (TiAIN) coatings based on hard nitride protect the tips or inserts from premature failure due to wear.

In particular, when machining very hard materials, the tools are very quickly exposed to overheating. Wear-resistant coatings such as titanium or zirconium offer even greater stability at high temperatures and resistance to oxidation.

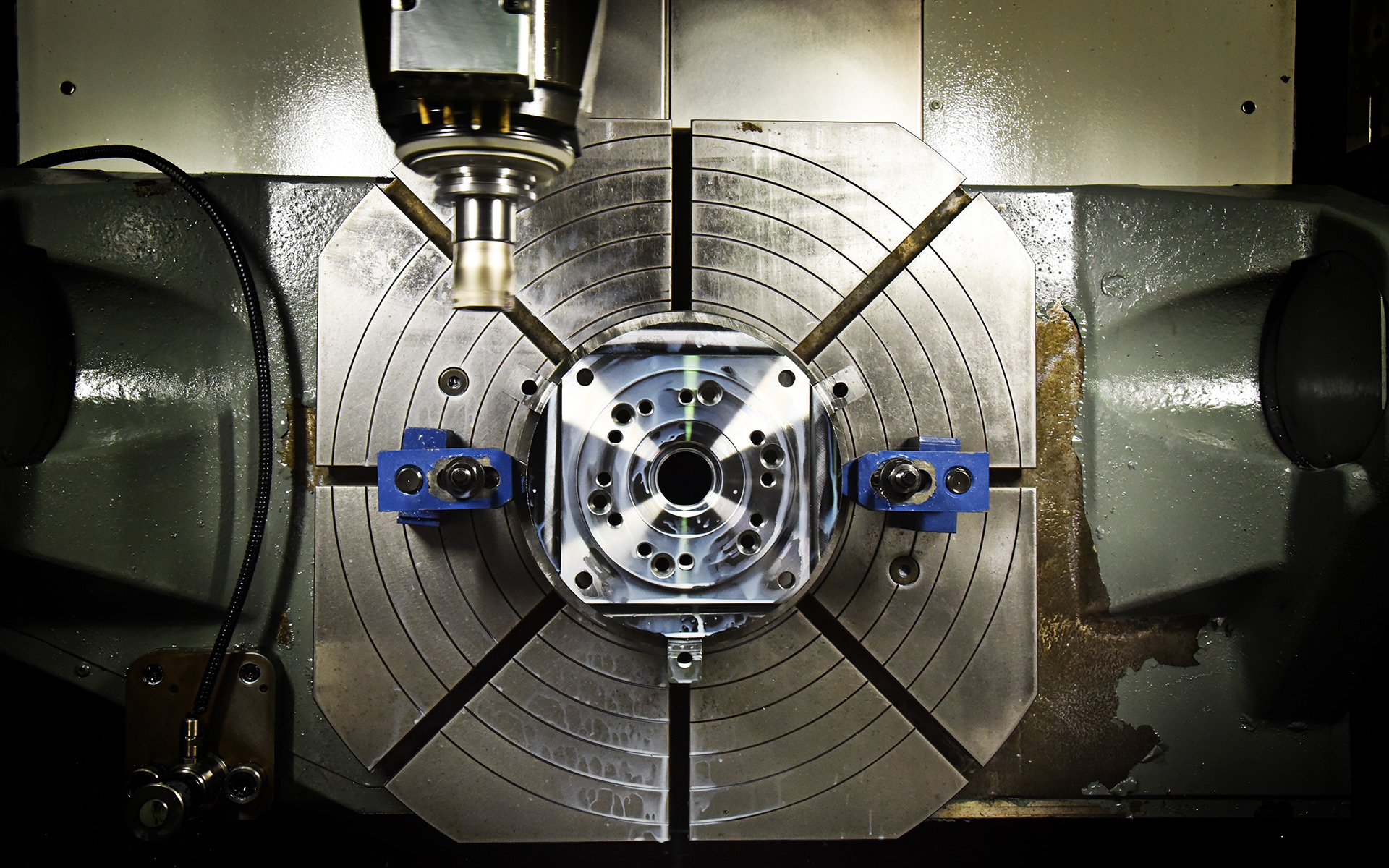

Zirconium coated inserts

Zirconium is a hard, corrosion-resistant metal with an appearance similar to that of steel. Used as an additive in steel, it is a very strong and extremely hard material that exceeds the best steel alloys for professional use.

Titanium coated inserts

Titanium is preferred because of its high ratio of breaking strength, high corrosion resistance, fatigue strength and ability to withstand moderately high temperatures without deformation. Titanium alloys are also commonly used in the aviation, aerospace, automotive, energy and rail industries.

Our company has the experience and knowledge to offer you the best standards of quality and correct proportion in treatment and coatings in different types of alloys and heat treatments.

Our company has demonstrated its quality assurance by meeting delivery times and deadlines.

85% of our offers become orders

We will give you a free quote without obligation