Cemented carbide

In the middle of difficulty lies opportunityThe hard metal body is formed either by pressing the powder or by injection molding techniques, and then sintered to full density.

Hard metals for machining applications contain more than 80% hard phase.

Cubic carbonitride is another important component, especially in sintered gradient grades.

One of the most important parameters for adjusting the hardness-tenacity ratio of a serious quality, the finer the grain size, the greater the hardness with a given binder phase content.

Too low a binder content can cause the material to be brittle.

Cubic carbonitride : Also called phase-γ, it is often added to increase heat resistance and to form gradients.

Gradients : are used to combine improved plastic deformation resistance with edge toughness. Cubic carbonitride concentrated in the edge improves heat resistance where it is needed most. Beyond the edge, a binder rich in tungsten carbide structure inhibits chip cracking and hammering fractures.

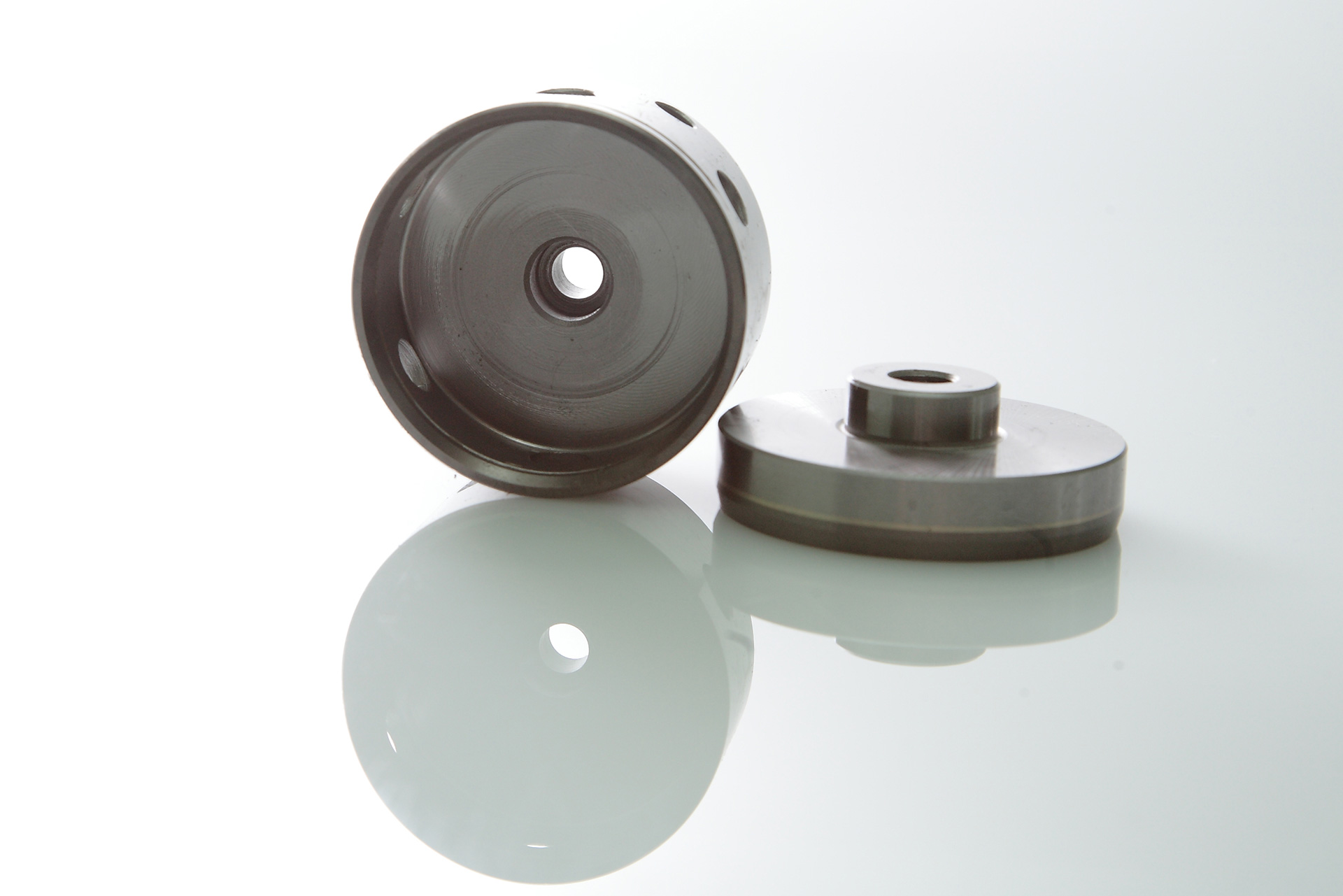

Hard metal fabrication

The manufacture of carbide inserts is a carefully designed process where geometry and quality are balanced to offer a product that fits the application perfectly.

Widia’s high performance carbide insert cutting tools.

We produce raw or semi-finished components according to customers’ designs – with maximum precision.

85% of our offers become orders

We will give you a free quote without obligation